The Role of Different Supplements in Expression Level of Monoclonal Antibody against Human CD20

-

Mahboudi, Fereidoun

Biotechnology Research Center, Pasteur Institute of Iran, Tehran, Iran, Tel:+98 21 66465132; Email: mahboudi@pasteur.ac.ir

Mahboudi, Fereidoun

Biotechnology Research Center, Pasteur Institute of Iran, Tehran, Iran, Tel:+98 21 66465132; Email: mahboudi@pasteur.ac.ir

-

Biotechnology Research Center, Pasteur Institute of Iran, Tehran, Iran

-

Azarpanah, Armita

-

Department of Research and Development, Aryogen Biopharma Company, Alborz, Iran

-

Maleknia, Shaian

-

Department of Research and Development, Aryogen Biopharma Company, Alborz, Iran

-

Vaziri, Behrouz

-

Department of Research and Development, Aryogen Biopharma Company, Alborz, Iran

Abstract: Background: Recombinant monoclonal antibodies have been marketed in last three decades as the major therapeutic proteins against different cancers. However choosing a proper medium and supplements to reach the high expression is a challenging step. Despite of commercial serum free and chemically defined media, there are still numerous researches seeking the optimum media to gain higher expression titer. Selecting the best basal media followed by proper supplementation to increase the cell density and expression titer needs proper and accurate investigation.

Methods: In this study, we have determined the expression titer of monoclonal antibody against human CD20 using soy extract, Essential Amino Acid, Non- Essential Amino Acid, Panexin NTS, Peptone, Yeast extract, Insulin-transferrin selenite, Human Serum Albumin, Bovine Serum Albumin, Lipid, and two commercially available supplements, Power and Xtreme feed. In each experiment, the expression level was compared with a well defined media, ProCHO5, RPMI 1640 and DMEM-F12.

Results: It has been shown that supplementing the ProCHO5 basal medium with 10% power feed or combination of 5% PanexinNTS,1.5 g/L yeast and 1.5 g/L peptone results in the best production levels with 450 and 425 mg/L of anti CD20 mAb expression level, respectively.

Conclusion: Panexin NTS, yeast and peptone cane be proper supplement for fed-batch cell culture instead of commercial Power feed supplement which is a cost effective way to increase expression level. And thereby ProCHO5 may be replaced with common media such as RPMI 1640 and DMEM-F12.

Introduction :

Recombinant monoclonal antibodies (mAbs) have been widely applied in diagnosis and therapy of many human disorders such as cancer, auto-immune and allergic diseases in recent decades. The production hosts for these proteins are common mammalian cell lines such as SP2/0 and Chinese Hamster Ovary (CHO) cells, mainly cultured in fed batch mode bioreactors 1. The high demands for mAbs along with their low expression yields have led many producer companies to perform the expression procedure in 10,000 L or larger volume bioreactors 2. Additionally, the expression titers have sharply increased throughout the improvements in the production process and media development 2. During the last three decades, extensive studies have endeavored to achieve high production titers through developing new media and appropriate supplementation strategies 3-5. Although fully chemically defined media have developed and employed in large-scale mAb production, not all antibody production cell lines have high expression titters in these chemically defined media 6. Therefore, many scientists attempt to increase productivity through enriching basal media with supplements. The familiar supplements for mammalian cell culture include variety of defined and undefined components such as human or bovine sera albumins, carbohydrates, amino acids, vitamins, minerals, lipids, buffers and proteins like growth factors and protein hydrolysates 7.

Serum as a major supplement has been implemented for mammalian cell cultivations in feeding stages of developing biopharmaceuticals. It contains several growth-promoting compounds like growth factors, nutrients and hormones 8. However, it has numerous disadvantages including a variation in shelf-life and composition from batch to batch. It also presents difficulties in the purification of the protein product and is often associated with high costs 9.

And last but not least, is the risk of viral, mycoplasma or prion contaminants which may induce a contagious risk to the biopharmaceutical product. Therefore, bovine serum and other animal derived raw materials should be preferably avoided if possible 8. Nevertheless, substituting all important components of serum with chemically defined elements has shown to be challenging since the growth requirements may vary widely between cell lines and sometimes between clones 10. Moreover, serum-free or even protein-free media often results in a decrease of specific productivity and sometimes changes in product quality 11. There is no universal serum-free medium which is applicable for all cell lines and each serum free media meets the specific requirements of an individual cell line 10. Addition of animal-component-free protein hydrolysates, as a substitute for serum has been tried to increase cell density, culture viability and productivity in an efficient manner 12. Protein hydrolysates are composed of amino acids, small peptides, carbohydrates, vitamins, and minerals, which provide nutrient supplements to the medium 6. Non-animal-derived hydrolysates from soy, wheat, and yeast are commonly used in cell culture media 6.

It has been shown that supplementation with the aspartate, asparagine, glutamate, and pyruvate feed maintained exponential growth for an extra day in addition to the increase in the Integral Viable Cell numbers (IVC) up to 26.8×106 cells/ml per day. More importantly, the antibody titer was boosted by 75% 13. Chen et al, demonstrated that combination of hypoxanthine and thymidine was able to stimulate initial cell growth to 6.45×106 cell/ml and elevate volumetric antibody production to 632 mg/L 14.

Lipid supplementation shows different effect on cell growth and protein expression in different cell lines 15. Lately, it has been shown that Nanoparticle Cholesterol Mixtures (NCM) enhanced the mAb expression by 64% 16. Insulin in combination with transferrin improves cell growth in majority of mammalian cells 17.

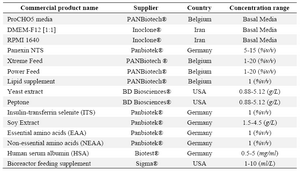

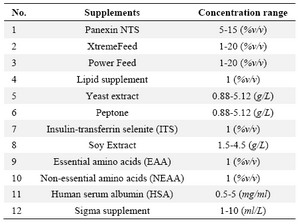

The present study aimed at providing a combination of supplements for anti-CD20 mAb producing CHO cells’ culture which increases cell density and enhances protein expression. We evaluated the effect of several additives and chemically defined commercially available feeds on CHO cells growth, viability, and metabolite profiles in suspension cultures of CHO-DG44 cells in 6- well plates and spinner flasks. Three different commercial media (RPMI 1640, DMEM-F12 and ProCHO5) were utilized as basal media. The utilized supplements and concentration range are listed in tables 1 and 2, respectively.

Materials and Methods :

Media development in 6-well plates:The experiments were performed in 6-well plates to investigate the optimum supplements’ concentrations. Table 1 summarizes the list of selected supplements and additives, for this study, commercially available by different suppliers. It should be pointed out that DMEM-F12, RPMI 1640 and ProCHO5 were distinctly tested as the basal media. For each additive multiple different concentrations were evaluated in order to get the optimum concentration with highest protein expression value (Table 2). The initial cell density in each well was 0.2×106 cells/ml with 1 ml starting culture volume. The plates were incubated at 37°C with 5% CO2 for 7 days. Plates were supplemented to provide cells’ nutritional demands up to 5 ml.

Antibody expression measurement:The protein expression was determined through in-house indirect enzyme linked immunoassay (ELISA). Briefly, 100 µl of different dilutions of standard and samples was added to each well and incubated for 1 hr at room temperature. Then, wells were blocked by addition of 150 µl skimmed milk (10% v/w). After incubation for 45 min at room temperature, the plate was washed for 5 times with Phosphate Buffer Solution (PBS) which contained 0.1% Tween 20 (PBST). Then, 100 µl of Horse Radish Peroxidized (HRP) conjugated goat anti-human IgG antibody (Milipore) with predetermined concentration was added to each well and incubated for 45 min at 300 rpm and 25C following by 8 times of washing with PBS.

Tetramethylbenzidine (TMB) substrate was added to start chromogenic reaction and resulted in evident color change to blue. Finally, the reaction was stopped by addition of H2SO4 (0.5 M) and the absorbance was measured at 450 nm.

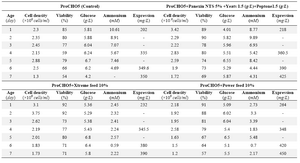

Media development in spinner flasks:The providers of all media and supplements are listed in table 1. ProCHO5 containing insulin is a non-animal origin medium for the growth of CHO cells. Lipid and L-glutamine were separately added to the media. "Xtreme feed for CHO cells" and "Power feed A with lipids" are two new supplements for sustaining cells. Panexin NTS® is a serum substitute providing nutritional requirements for CHO cells. Initial experiments were carried out in 6-well plates in order to find optimum concentrations of different additives in ProCHO5 medium. The final goal of this study was to gain insight into the impacts of different additives in chemically defined media in the fed-batch mode. Therefore, four extra groups of experiments were performed in 250 ml spinner flasks (Integra, Switzerland) in order to improve CHO cells’ growth and mAb production. The first spinner was supplemented with Panexin NTS (5% v/v), yeast (1.5 g/L) and peptone (1.5 g/L) in ProCHO5 medium, the second and the third spinners contained Xtreme and power feeds (10% v/v), while the fourth spinner had ProCHO5 media as the control group. The working volume in all experiments was 55 ml with initial cell density of 0.4×106 cells/ml. The spinners were incubated at 37°C and 75 rpm with 5% CO2 in a fed-batch mode. Daily analysis of the samples included cell density and viability determination, metabolites profile, and product titers.

Data analysis:During the cultivation samples were taken for analysis. The cell concentration and viability was determined by trypan blue-dye exclusion method. Glucose concentration was measured enzymatically using glucose kit (91014, Pars Azmon, Iran). Ammonium concentration was determined enzymatically using the ammonium kit (11 112 732 035, R-Biopharm, Germany). The expression titer was analysed using in-house indirect ELISA described earlier.

Statistical analysis:All experiments have been done in duplicate, and data are expressed as means± Standard deviation (STD). Data are analyzed using the nonparametric F-test and only p- values <0.05 were considered statistically significant.

Results :

CHO cells expressing monoclonal antibody against human CD20 were cultivated with 200,000 cells/ml initial cell densities for 7 days in three basal media: RPMI 1640, DMEM-F12 and ProCHO5. Different supplements were applied during the batch according to table 2. The optimum concentration of each supplement was picked up for supplement combination based on previous study (data not shown). Except for the control wells, fed with basal media alone, the rest of the wells were fed every 48 hr after 72 hr of cultivation.

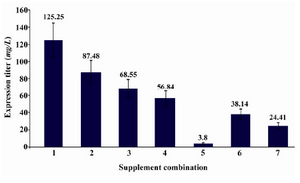

Figure 1 shows the titer of the antibody expression in CHO cells cultivated in DMEM-F12 with different supplements. Antibody titers were measured on 7th day of culturing, and DMEM-F12 alone was used as the control in this experiment. The highest expression, 125 mg/L, was obtained from DMEM-F12 supplemented with 5% Panexin NTS, yeast extract and peptone at 1.5 g/L final concentrations of each. As figure 1 shows this amount of expression is 5 times greater than the same in non-supplemented group (DMEM-F12).

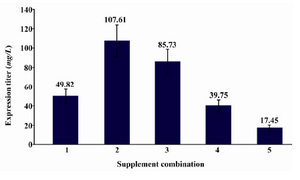

RPMI 1640 is another common basal medium for CHO cells. The recombinant CHO cells expressing monoclonal antibody against CD20 were cultivated in RPMI1640 with different supplements as mentioned in figure 2. The supernatants were analyzed for the level of expression on day 7 of culture. The highest expression, 107 mg/L, was obtained with RPMI 1640 media supplemented with Panexin NTS 5%, yeast extract (1.5 g/L) and peptone (1.5 g/L) (Table 3). The mAb expression titer was increased 6 fold from 17 mg/L in control group to 107 mg/L by these feeding strategies as shown in figure 2.

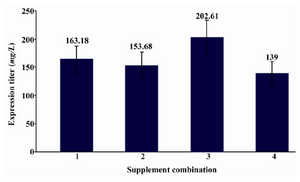

The effect of supplementing ProCHO5 basal medium with different nutrients was evaluated in another set of experiments. The result shows again that the titer of anti C20 has the highest amount in the presence of Panexin NTS 5%, yeast extract (1.5 g/L), and peptone (1.5 g/L), i.e. 202 mg/L (Figure 3), almost 68% increase in mAb titer compared with ProCHO5 without any supplements.

In the first part of this experiment, we tested different supplements with various concentrations to get the highest titers. There are also other commercially available feed media in the market such as Xtreme feed and Power feed. The optimum concentration of these feeds was determined with another set of experiment with ProCHO5 as a basal medium. The concentration of 10% v/v was chosen for next step (data not shown). In the next step, the new set of experiment was performed in 250 ml spinner flask taking into account the possibility of future scale-up (Table 3). The highest mAb titers, 450 mg/L, were obtained with Power feed 10% followed by ProCHO5 supplemented with Panexin NTS 5%, Yeast 1.5 g/L and Peptone 1.5 g/L, 425 mg/L, while the expression in ProCHO5 without any supplement was 350 mg/L. The antibody titers were increased significantly (1.2 times) in the presence of Power feed 10% and Panexin NTS 5% with Yeast 1.5 g/L and Peptone 1.5 g/L.

Discussion :

The recombinant monoclonal antibody (mAb) has therapeutic efficacy in the level of hundreds of milligrams. At the same time, because of their wide application, there is gradual a increase in the world demand for mAb 1. This means that the production scale or the expression titer has to be increased. Mammalian specific productivity was reported around 10-20 pg/cell/day in early 1990 18. Nowadays, optimization of recombinant protein expression with cell culture and process development has resulted in the specific productivity as high as 100 pg/cell/day 18.

Several strategies have been defined to increase the expression titer for monoclonal antibodies such as improvement in strain selection and optimization of culturing process 18. Optimized nutrient level in the medium also has dramatic effect on cell density and productivity 1-6. Utilizing the proper media with sufficient nutrients increases the efficiency of cell culture processes which can be measured by the productivity of the culture. The changes from complex media supplements such as animal-based serum to chemically defined feed media has created a great effect on the cost of downstream process as well 8,9.

In this study, the effect of different chemically defined supplements and feed media on the expression titer of a monoclonal antibody against human CD20 was investigated. To increase the productivity, the selection of basal media was the first step to be taken. Three most common basal media RPMI 1640, DMEM-F12 and ProCHO5 were compared with each other. It is well known that ProCHO5 is an enriched medium with high glucose, lipid, essential amino acid (EAA) and non-essential amino acid (NEAA). Therefore, it was expected that higher productivity would be achieved by applying this medium. The results approved the expectation. According to figures 1, 2 and 3, the expression titer for this antibody in these three media without any supplement was, 17, 24 and 139 mg/L in RPMI 1640, DMEM-F12 and ProCHO5, respectively.

Based on Shibuya et al's experiment, adding essential amino acids, vitamins and inorganic salt improves mAb expression up to 400 mg/L and the Maximum Viable cell Densities (MVD) will reach 3×106 cell/ml 9. Earlier investigations lead to MVD and expression titers of 7.5×106 cell/ml and 551 mg/L, respectively, through supplementing media with essential amino acids and vitamins 19. The present study also shows mAb expression titer doubled by supplementing with EAA and NEAA. Lipid can boost this effect up to threefold.

Adding peptone as a source of non-animal hydrolysates to media increased antibody production from 580 µg/ml to 1.2 g/L in a 14-day shaker flask fed-batch culture 20. Ballez et al showed that wheat derived hydrolysate are able to improve protein expression up to 65% compared to the basal medium 21. Kochanowski et al showed that the combination of yeast extract and yeastolate results in increased harvested antibody concentration up to 290% 22. According to the present study, addition of yeast extract and peptone to DMEM-F12 and RPMI 1640 had significant effect in enhancing the titer of antibody against CD20. A 2.8 fold increase in expression level has been obtained in the presence of yeast extract and peptone compared with RPMI 1640 without any supplement (Figure 2). It was found that a 6.1 fold increase can be achieved by adding 5% of Panexin NTS to these two supplements. The same enhancement, 5.1 fold increase, was found when DMEM-F12 is supplemented with Panexin NTS (5%), yeast (1.5 g/L) and peptone (1.5 g/L) combination. It is to be noticed that the titer of antibody is almost 10% lower than the one obtained with ProCHO5, 139 mg/ml.

The combination of Panexin NTS (5%), yeast (1.5 g/L) and peptone (1.5 g/L) was also added to ProCHO5 to examine the effect on the expression titer. It was shown that a 1.5 fold increase in protein titer, 202 mg/L, in the presence of these three supplements can be obtained. Therefore, the presence of yeast extract and peptone can be considered as the two major components that may be used to increase the level of expression.

The achievements in media development and optimization are valuable if they can be implemented on a large scale in bioreactors. Before scaling up, the culturing media should be developed in a smaller scale such as spinner flasks. The spinner flasks are the most proper system to mimic the culturing process in bioreactors. Based on our findings, ProCHO5 could be considered as the best basal media to increase the titers for this antibody. Two commercially available other protein- free supplements were studied in addition to Panexin NTS (5%), yeast (1.5 g/L) and peptone (1.5 g/L) combination. The highest expression titer was achieved by adding Power feed with 450 mg/L. The titer with Panexin NTS (5%), yeast (1.5 g/L) and peptone (1.5 g/L) was 425 mg/L. The difference between these two is not that significant in the terms of expression enhancement. However 14% increase in the level of titer with Power feed compared with Xtreme feed and 23% increase compared to ProCHO with no supplement were observed. This means that the combination of Panexin NTS, yeast and peptone can be used as a feed in bioreactor instead of commercial Power feed supplement, as a cost effective way to increase expression level.

Conclusion :

It may be concluded that addition of these three components to one cheap base media like RPMI and DMEM-F12 can be substituted with an expensive media such as ProCHO5.

Acknowledgement :

This work was the part of project 9001001a, which was supported by Aryogon Bipharma Company.

Figure 1. Expression of recombinant mAb against h-CD20 in DMEM-F12. Recombinant CHO cells have been grown in DMEM-F12 and fed with different supplements. 0.2×106 cells/well seeded in 6-Well plate and cultured for 7 days.

Supplement combination:

1. Yeast (1.5 g/L)+Peptone(1.5 g/L)+NTS (5%)

2. Yeast (1.5 g/L)+Peptone(1.5 g/L)+Sigma supplement (0.1%)

3. Yeast (1.5 g/L)+Peptone(1.5 g/L)+ITS(0.1%)

4. Essential amino acid (1%)+ Non-essential amino acid (1%)

5. Essential amino acid (1%)+ Non-essential amino acid (1%)+Lipid (1%)

6. Human Serum Albumin (HSA)(3%)+Sigma supplement (0.5%)

7. Control (DMEM-F12)

|

Figure 2. Expression of recombinant mAb against h- CD20 in RPMI 1640. Recombinant CHO cells have been grown in RPMI 1640 and fed with different supplements. 0.2×106 cells/well seeded in 6-Well plate and cultured for 7 days.

Supplements combination

1. Yeast (1.5 g/L)+Peptone (1.5 g/L)

2. Yeast (1.5 g/L)+Peptone (1.5 g/L)+NTS (5%)

3. Yeast (1.5 g/L)+Peptone (1.5 g/L)+Sigma Supplement (0.1%)

4. Human Serum Albumin (HSA) (3%)+ Sigma supplement (0.5%)

5. Control (RPMI 1640)

|

Figure 3. Expression of recombinant mAb against h- CD20 in ProCHO5. Recombinant CHO cells have been grown in ProCHO5 and fed with different supplements. 0.2×106 cells/well seeded in 6-Well plate and cultured for 7 days Supplements combination

1. Peptone (1.5 g/L)

2. Yeast (1.5 g/L)+Peptone (1.5 g/L)

3. Yeast (1.5 g/L)+Peptone (1.5 g/L)+NTS (5%)

4. Control (ProCHO5)

|

Table 1. Different media and supplements were used in present study

|

Table 2. Supplements and concentration ranges used in 6 well-plate cultivation with DMEM-F12, RPMI 1640, and ProCHO5. Detailed data of combinations and related concentrations increased the production yield are tabulated in tables 3-5

|

Table 3. Cell density, viability and expression in ProCHO5 with different supplement, cells were cultured in 250 ml spinner

|

|